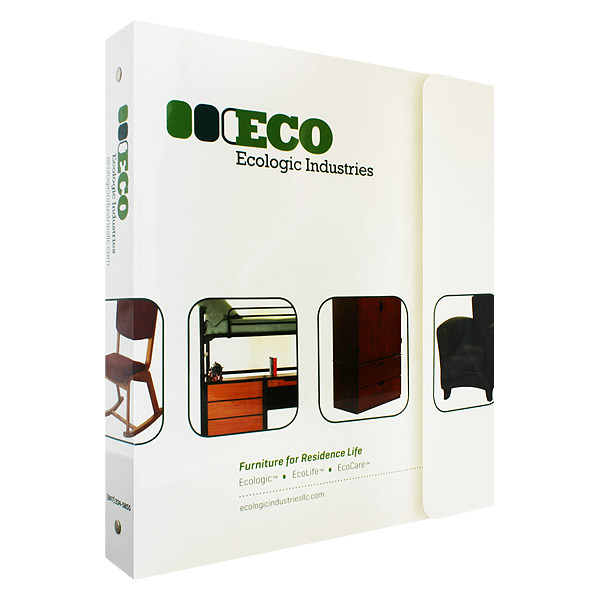

Nobody wants to have to replace something they bought due to inferior craftsmanship — therefore, heavy duty binders are your best bet if you want a durable marketing tool that lasts a long time. Wear-and-tear is unfortunately par for the course, so your binder should be able to withstand the normal weathering that afflicts any printed marketing tool. If you don’t know what provides the best durability, here are a few things to look for to help you make the best possible custom presentation binders.

Choose a protective coating for your binder to make it last longer and protect it from smudges, fingerprints and scratches.

Protective Coatings

Adding a protective coating to your finished binder design can add an extra level of durability, depending on your choices. Aqueous coating is a water-based coating that can protect the surface of your materials from scratches, smudges, fingerprints and general weathering. However, aqueous coating will not protect your binder much from liquids or other spills. Apply laminate coating for a sturdier, thicker coating that is water-resistant, allowing you to wipe down the binder with a damp cloth to keep it clean.

Stock Choices

Heavy duty binders are made with durable materials like vinyl, leather or poly material. However, these materials do not always suit your binder’s aesthetic needs. If you decide to go with a paper binder, the default paper stock for a binder is at 18-point thickness, which provides a stiff, crisp binder that holds its shape without being brittle. Going too thick for your stock can cause the binder cover to crack or break, while a stock that’s too thin makes your materials flimsy.

Check the quality of your three-ring binding so that its strong enough to hold all of your files.

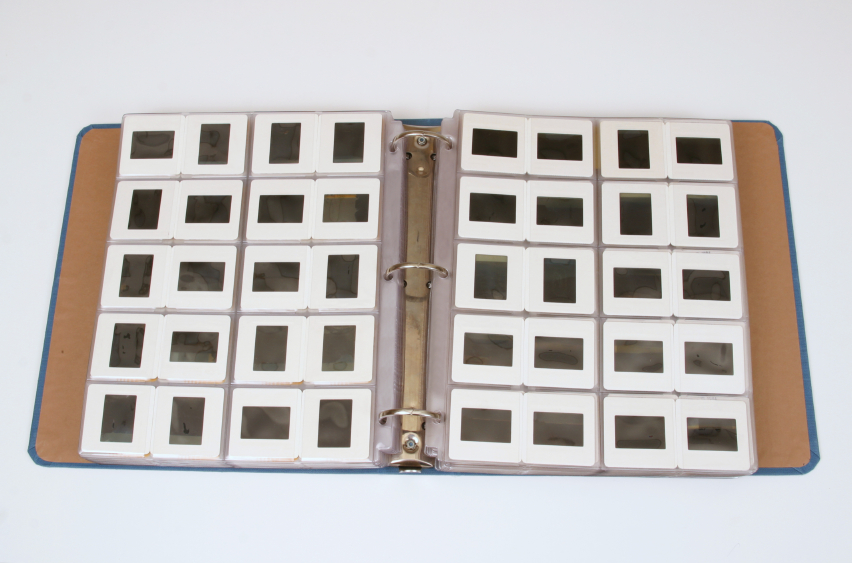

Quality of Binding

It doesn’t matter how sturdy your binder cover is if it completely falls apart on the inside. A strong binding mechanism is found in all heavy duty binders — one that can be opened and closed multiple times without breaking. The adhesive that holds your binder’s pockets and other accessories together should also be strong so that the pockets don’t become detached. Ask for a sample and inspect the sturdiness of the binding and glue to make sure it’s to your liking.

Reinforced Edges

Another way to make your binders more durable is to outfit them with a reinforced edge. Reinforcing your edges makes them less susceptible to tearing and prevents the edge from looking ragged from frequent use. The binder’s edges are folded over from the front cover into the interior and then glued down. If there are pockets in the interior of your binder, the reinforced edge will help to fortify them so that they aren’t accidentally torn from the binder.

Binder sleeves help you store and protect the contents of your binder.

Durable Add-ons

Sometimes, even heavy duty binders can use some assistance in keeping their contents free from damage. Consider add-ons and accessories that help to increase the lifespan of your binder. Put stick-on reinforcements on the holes of your documents so that they aren’t accidentally ripped out of the binder, or use reinforced binder sleeves to store your files. A slip case is a protective accessory that goes over your binder to maintain its shape and integrity, while providing a sort of armor for the binder itself.

The best way to find out if a binder is durable or not is to obtain a free sample and test it yourself. Put your heavy duty binders through the ringer and find out which one is the sturdiest before committing to an order.

This post is a part of our Binders 101 product guide.